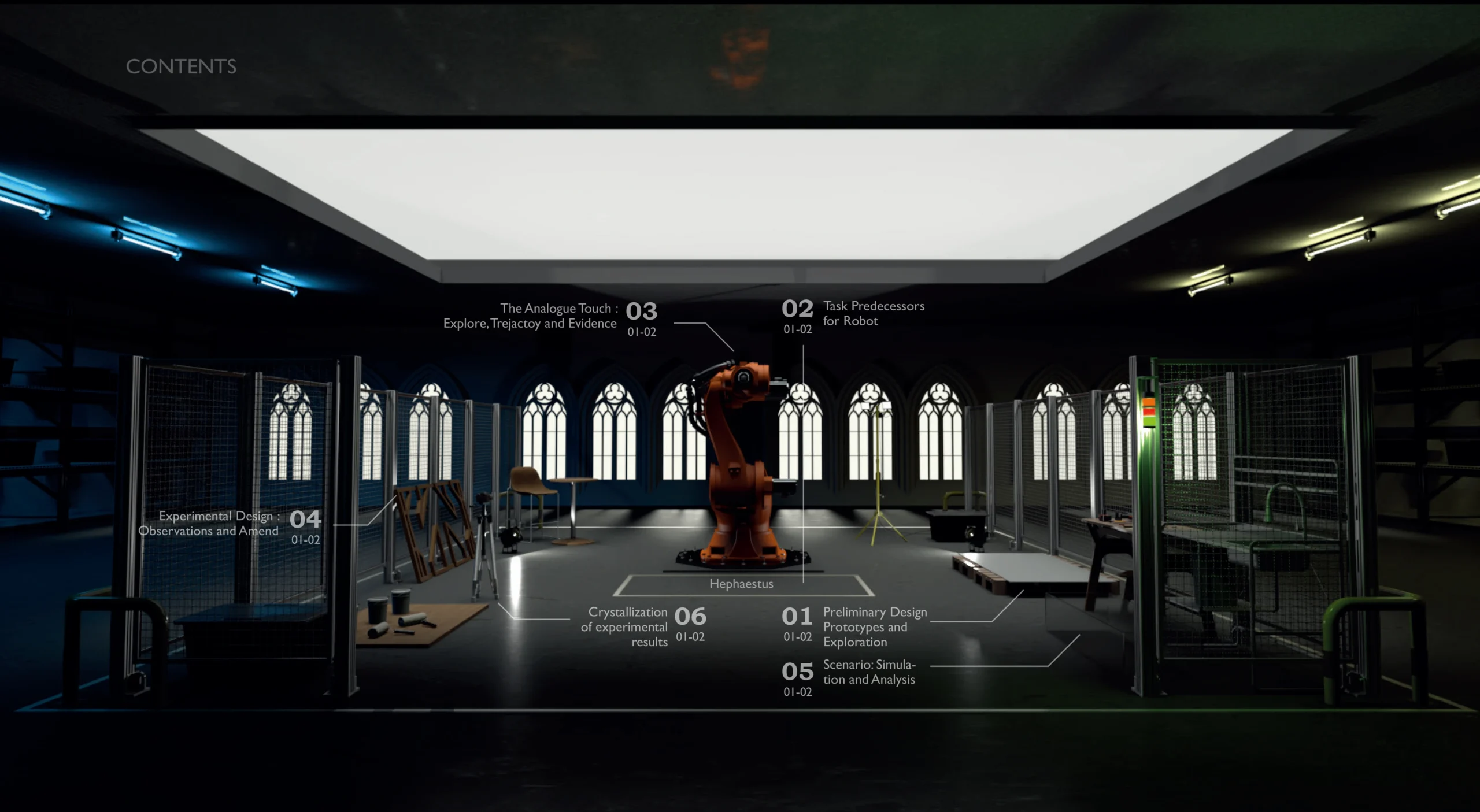

PROJECT ABSTRACT & contents

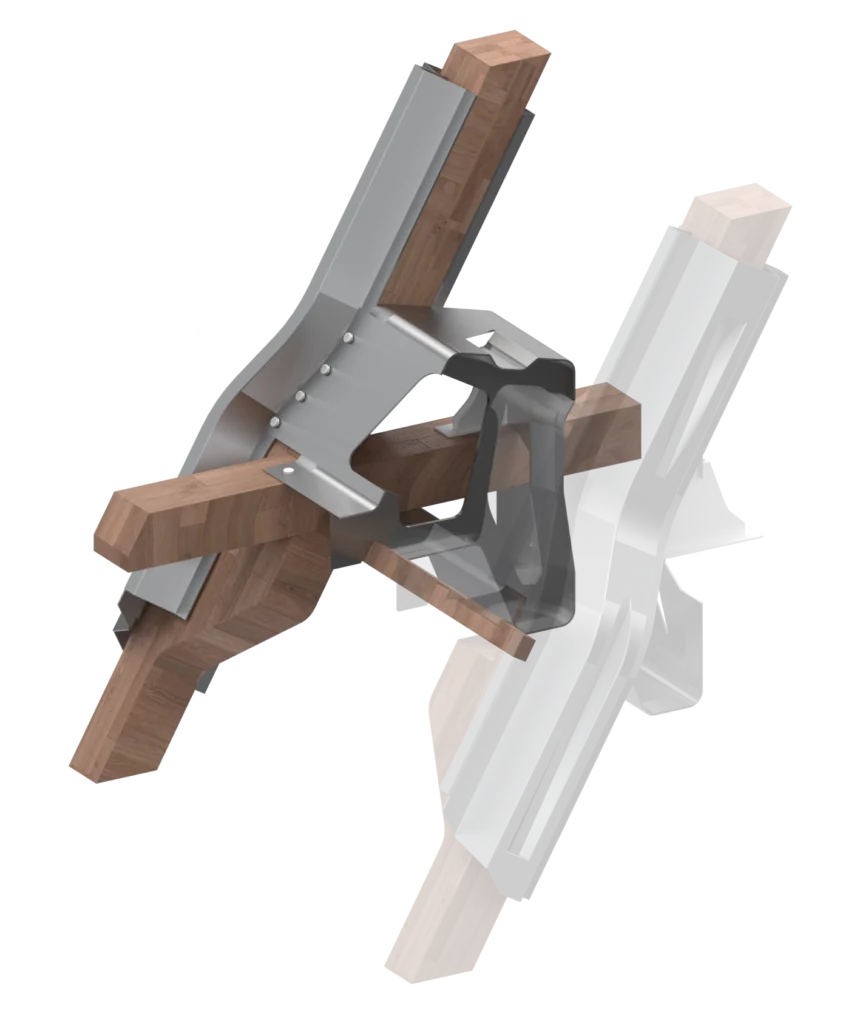

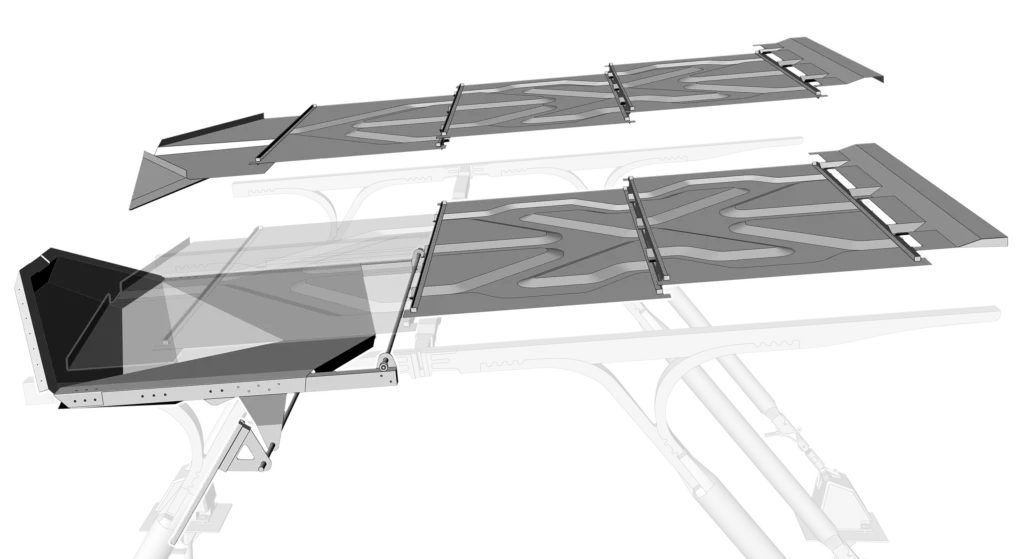

The structure choreographs the interrelationship with water whilst furnishing the woodland with the infrastructure to facilitate timber production, by protecting wood from rainfall.

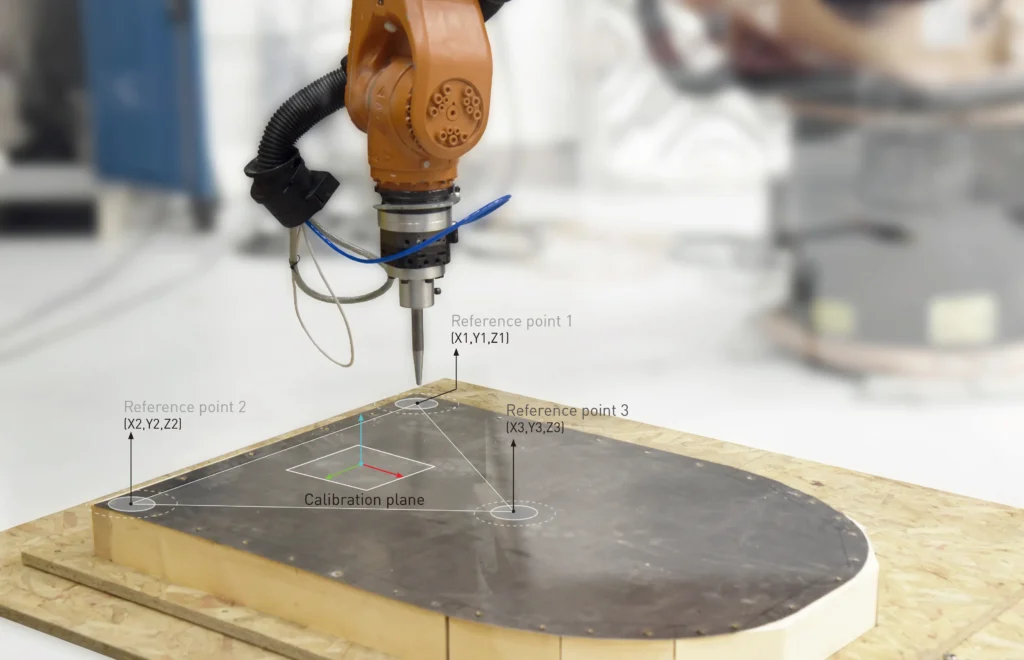

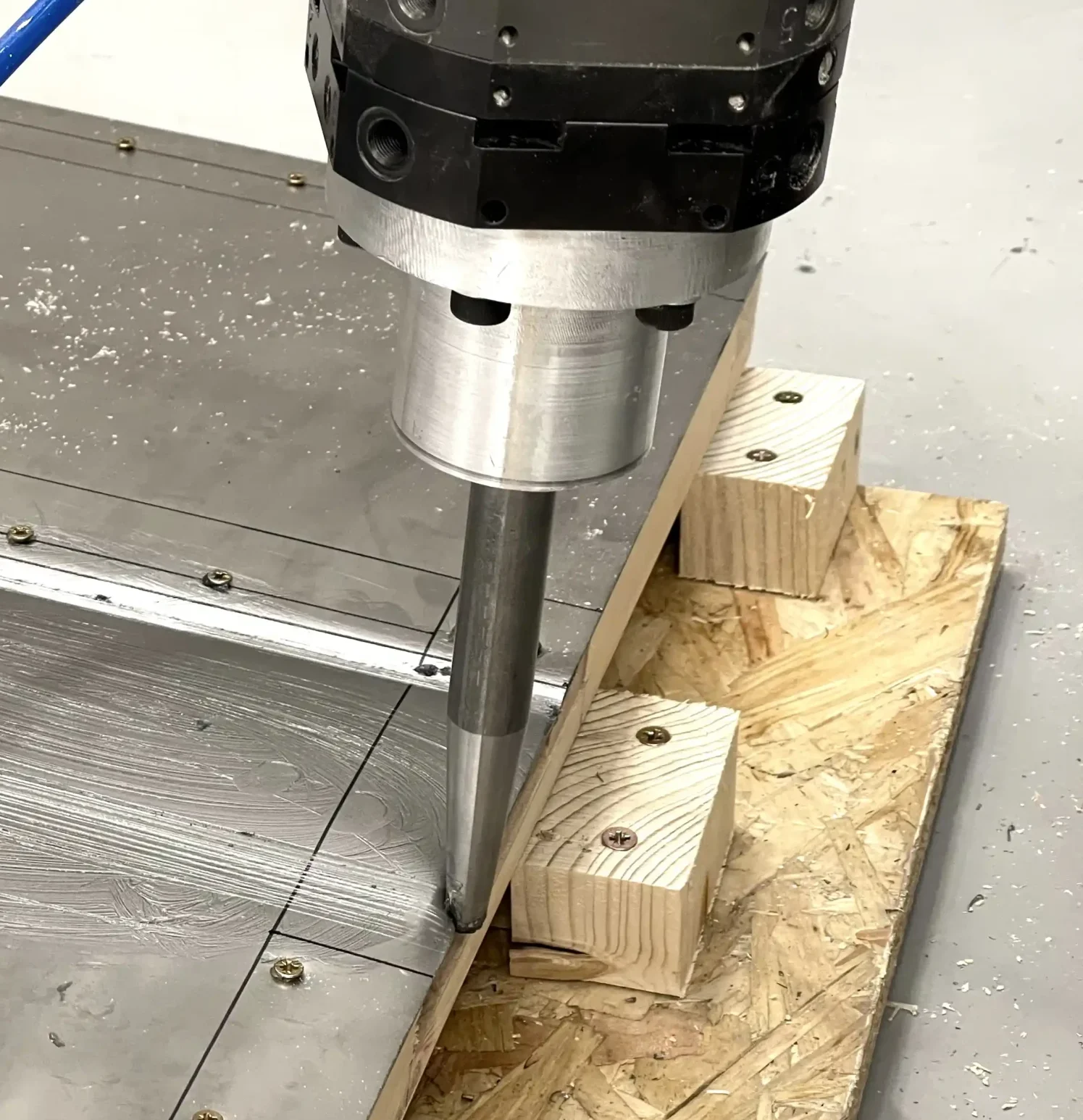

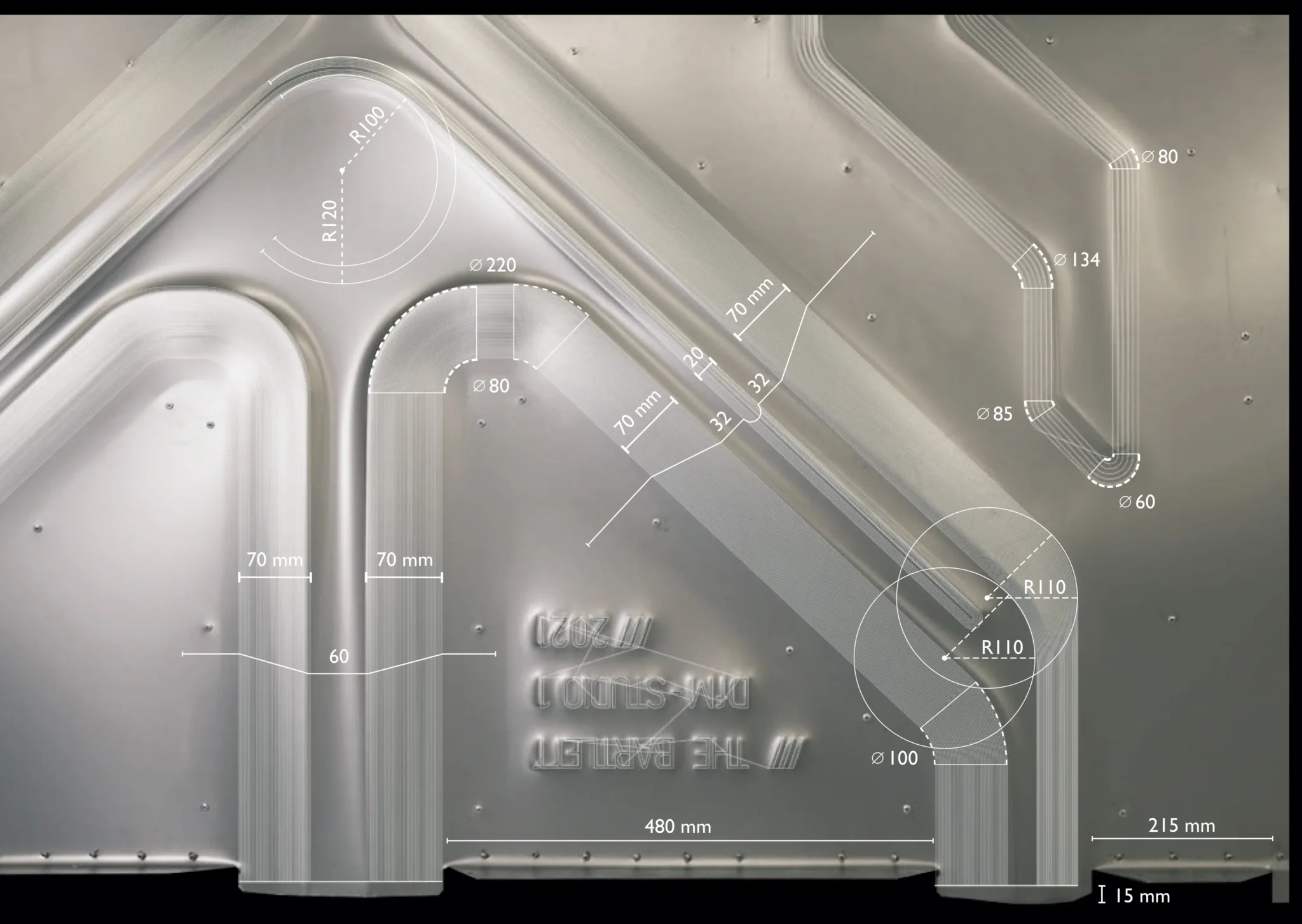

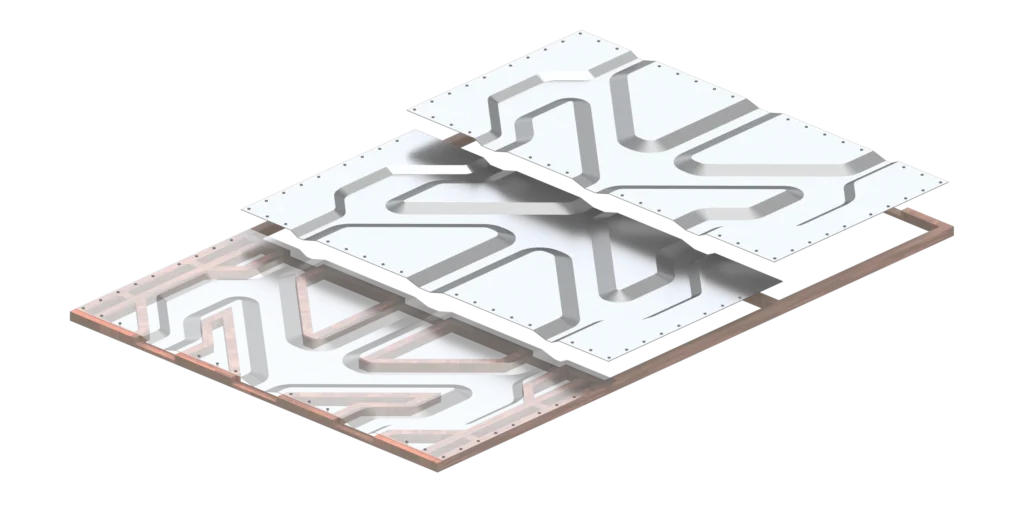

I used the 1mm thickness Mild-steel sheet as the primary material and used the Robotic Incremental Sheet Forming as the primary production method.

To use mechanical arms to pressurize to create a pattern with structural strength on the steel plate, to reduce the density of the beams that are loaded by the scaffold structure.